AC cooling fan introduction - Fulltech Electric

Cooling fan has been the major components of different kinds of industrial products, such as electrical machinery and electronic products which all requires cooling fan as the major device for thermal management. By creating the air flow, cooling fan provides cool air to lower the temperature of the industrial equipment, also, helps the industrial electric or electronic projects to keep the high efficiency and its performance will not be lowered due to the heat generated.

As the part of the electronic components, AC fans are widely designed in the home appliance or different kinds of industrial electronic machinery. It is because AC fan can provide stable air flow continually, which helps to stable the machinery performance, so the machinery will not be out of function due to the overheat.

AC fan works with AC power, and by running of the impellers to create air flow to lower the temperature of the machinery, and prevent the machinery from overheat. The different between AC and DC fan is – AC fan air flow is stable and continually, which can average the machinery temperature. Also, by adjusting the fan speed to meet the purpose of thermal management.

AC fan can be categorized in 3 major models, based on its design –

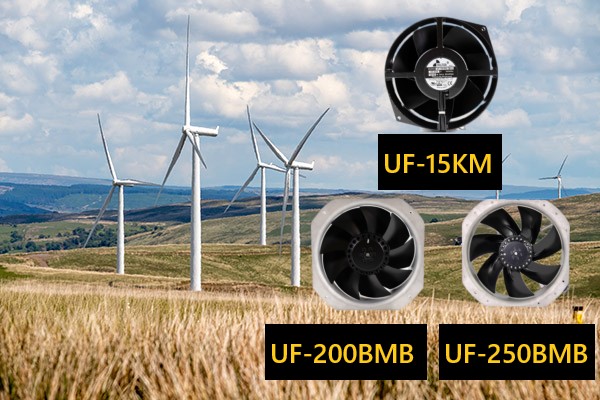

AC axial fans – the air flow it creates is vertical with the fan impeller, the air in and out is in the same direction. Axial fans’ main advantages are – big air flow, easy assembly, high efficiency, and high speed. With multiple product selection with different air flow and speed, it allows the users to choose the axial fans meets their requirements most. External rotor axial fans provides stronger air flow and higher speed, and with metal impeller design, it fits better for customers who need to use the fans in a rugged circumstance.

AC cross-flow fan the air-in direction is horizontal with air-out. The design of impeller and air-out area is narrow, which fits most to install on the flat machines, like elevators, industrial bag-blowing machine and so on.

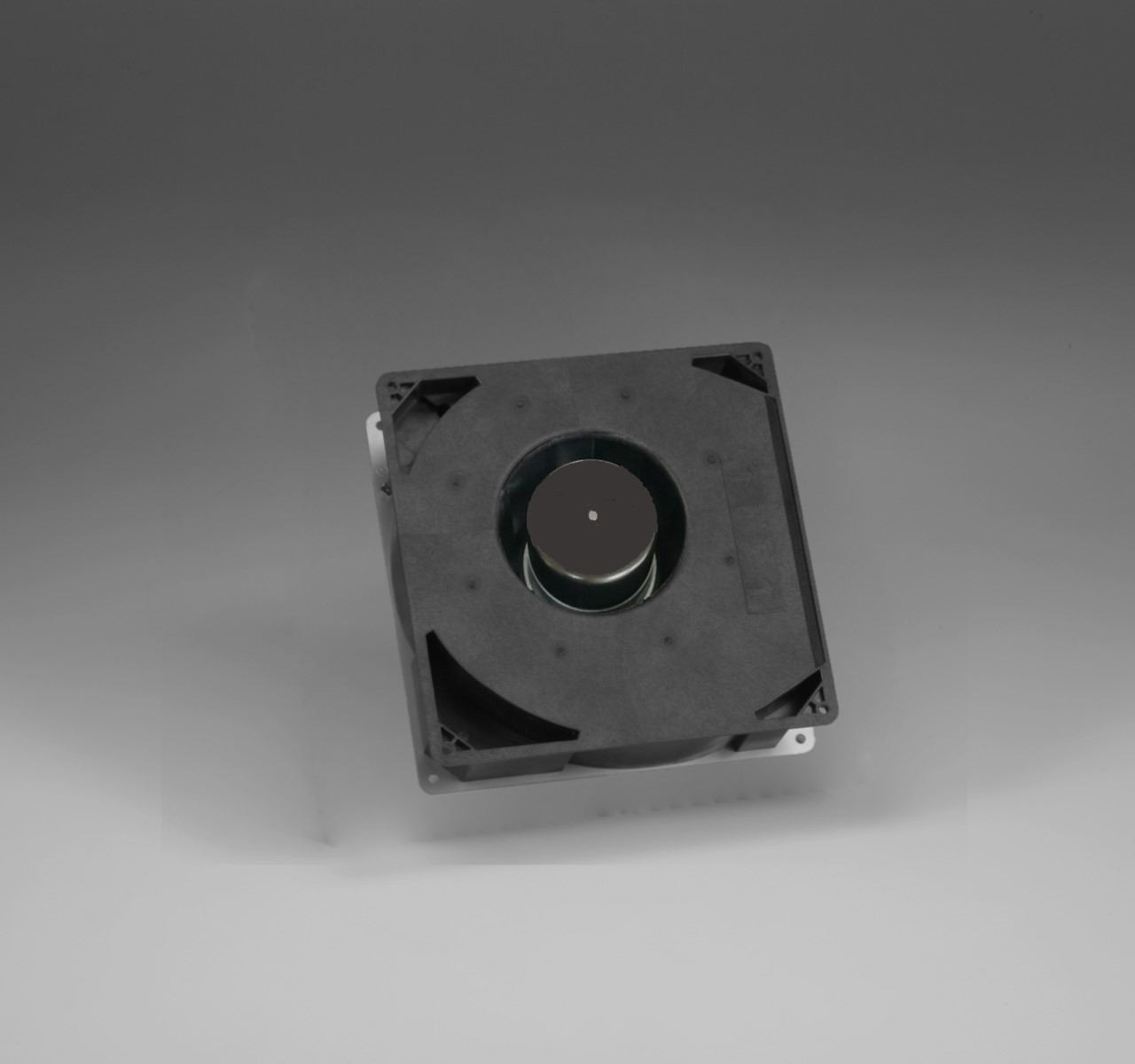

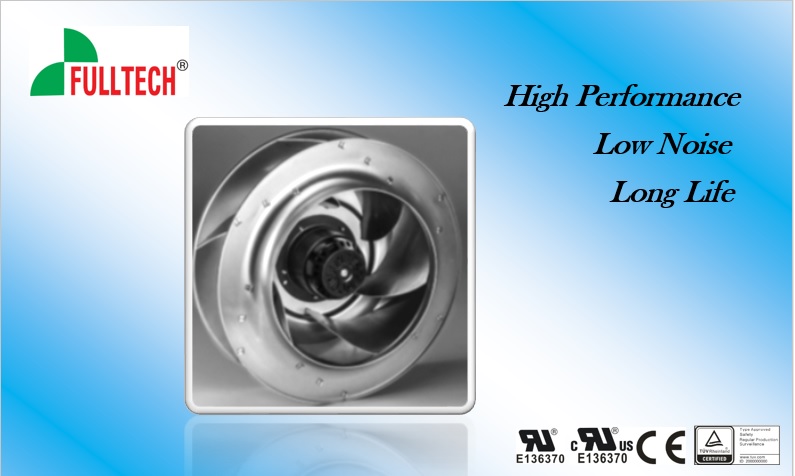

AC centrifugal fans with its backward-inclined design, the air sucks in from the center of the impellers, by its centrifugal inertia, the air comes out through the edges of the impellers. With the 90 degree structure design of air inlet and air outlet, it fits better for the industrial fan users with special design requirement.

AC blower fans same backward-inclined design like centrifugal fans, with the design of air flow concentration, the air blows further.

AC roof fan it is same backward-inclined design, but fits better for home appliance for air exchange, exhaust, and so on.

EC fan

EC fan is a new technology in those years, EC fan has the advantages of AC fan and DC fan, which is EC fan can convert AC power input to DC power output by the way of electronic rectification, to meet the goal of energy saving. It also means, the longer EC fan uses, the more energy it saves. Also, EC fan will not be limited by frequency as AC fan does, it allows EC fan to perform with higher RPM but with less power consumption. And EC fan motor design is similar with DC motor, so, the motor will be with less consumption of the ball bearing, and with better life expectancy than AC fan.

EC fan feature:

1. More than 50% energy saving than AC fan

2. Better RPM performance with less limitation than AC Fan

3. Customized speed control Design

4. Better Life Expectancy than AC fan

5. Less temperature rising than AC fan

More and more users choose to install the machines or equipment in the outdoor, for example, electric cabinet for solar panel, heat exchangers, electric control cabinet, LED billboard outdoor and so on. Those equipment uses the AC fan inside to intake and exhaust the air to cool down the equipment. However, by installing the equipment outdoor, it increases the risk the malfunction of the machines as well, so it is important to choose the right AC cooling fan to guarantee the life cycle and durability of the industrial equipment. And AC fan with waterproof made by Fulltech can help to eliminate the risk of the malfunction which may be caused by the rain or humidity inside the machine.

Fulltech AC axial fan is waterproof by sealing the motor inside, to avoid the possibility of the malfunction of the AC fan. Also, Fulltech AC fan passed the constant temperature and humidity test, -20℃~70℃ for 15 cycles and for 300 hours in total. It proves that Fulltech AC axial waterproof fan is reliable in the various outdoor environment.

AC cooling fan with ATEX compliance

EU announces the ATEX directives for the industrial equipment which may be used in the explosive environment and may cause the safety doubt. The ATEX directives defines the particles which can cause the explosion easily, such as powder dust in the air, flammable gas, flammable vapor or mist and so on, as potential dangerous or explosive environment. All mechanical machinery or electrical equipment, including the electronic components which will be installed in the potential explosive environment will need to be well protected.

Many customers use AC fan as the cooling device for the refrigerator system, however, due to the necessity of the refrigerant in the refrigerator, the users have to exclude the all possible explosive factors, to avoid the possible explosion. And it will be great help to eliminate the risk of the explosion of the machinery or equipment if the AC fan with ATEX compliance is chosen. Fulltech is developing the AC fan with ATEX compliance by 100% protection of the motor, to prevent the fan to interact with the possible explosive factor and make sure the refrigerator system can be used continually and safely.

How to choose AC fan fits your requirement most -

The efficiency of AC fan is very important nowadays, since more and more function and components are required in the small space, like for the cabinets, electronic components or eve for industrial electronic devices, it will generate more heat while running the device. In order to do that, AC fans will have to have ultimate performance in a limited space to have the best thermal management performance.

As the design engineer for thermal management device, he will choose the AC fan per ventilation and cooling system requirement First, engineer will have to verify the power input is AC or DC. Then, the frequency is 50Hz or 60Hz, and main AC power input is 115Vac or 230Vac, and then engineer will choose AC cooling fans based on the size, air flow, statistic pressure and so on. The most popular fan size will be 120x38mm, 80x38mm, 254x89mm, 172x150x55mm, 60x30mm, 92x25mm, 225x80mm, 190x70mm, and if AC fans will be used in a rugged circumstance, the engineer may choose the fans with metal impellers. If AC fans will be used in a high humid environment, then, the engineer can choose AC fans with waterproof. Especially, in those couple years, more and more requirements for green technology, so the engineer may consider the EC fan for the purpose of energy saving.

About Fulltech Electric Co., Ltd.,

As the leading manufacturer of AC fans in Taiwan, Fulltech insists to provide the AC fans with best quality and competitive price to our worldwide clients in all industrial equipment industries and home electronics industries, through our dealers in the world. Fulltech provides AC tube axial fans, backward inclined centrifugal fans, AC cross-flow fans and also EC fans, customized service is also welcome, to meet our clients need.

If you need to know more about Fulltech AC fan, you may download our product catalog on our website.

Or please don’t hesitate to contact with us direct or through our worldwide electronic component distributors.

You may be interested in the related article:

1. Difference between AC, DC and EC cooling Fan

2. What is ATEX

3. Waterproof AC Cooling Fan for Refrigerator/ Freezer

1. Difference between AC, DC and EC cooling Fan

2. What is ATEX

3. Waterproof AC Cooling Fan for Refrigerator/ Freezer

or you can contact us for total solution